In the capital-intensive world of mining, the tension between operational efficiency and sustainability has long been accepted as a fundamental trade-off. The conventional wisdom dictates that robust Environmental, Social, and Governance (ESG) performance comes at a cost, often pitting profitability against corporate responsibility. This paradigm, however, is being rendered obsolete by technological innovation.

A groundbreaking materials science solution from SCGC is proving that durability, cost-efficiency, and environmental stewardship are not mutually exclusive pursuits. Our patented polyethylene compound, SCGC™ HDPE S999PC, designed specifically for high abrasion resistance, demonstrates that superior engineering can deliver both financial and ecological returns, creating a powerful competitive advantage.

A Leap in Performance and Durability

For any industrial operation, infrastructure longevity is a cornerstone of financial planning. In mining, where abrasive slurries constantly wear down transport pipelines, replacement cycles of just two to five years are a significant and recurring operational expenditure. Standard HDPE pipes like PE100, while reliable, have a well-defined limit to their service life.

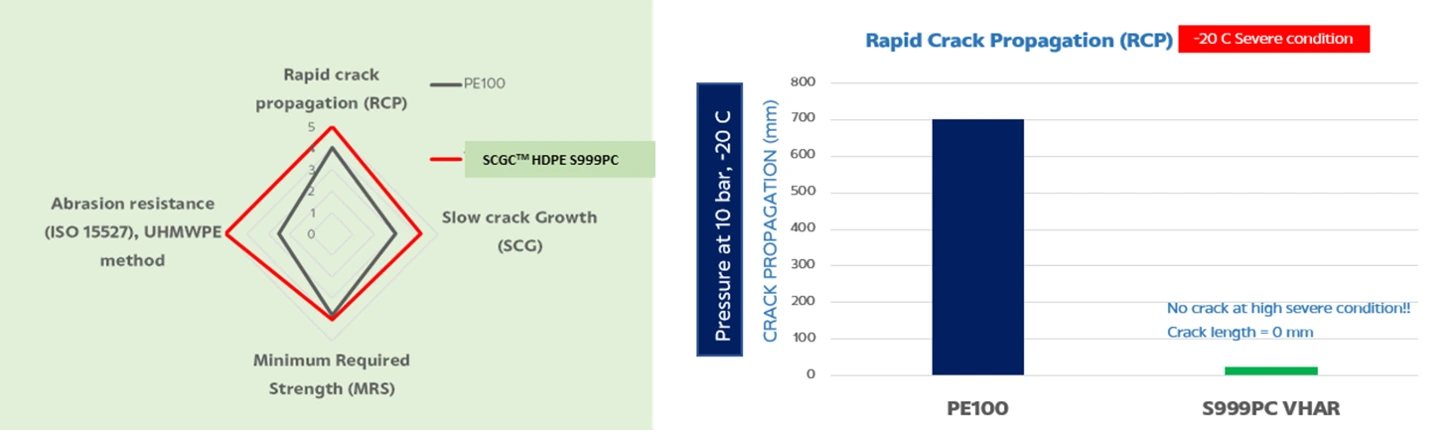

SCGC™ HDPE S999PC represents a quantum leap beyond this standard. Certified lab tests and simulations confirm it offers 2.3 times greater abrasion resistance than conventional PE100 equivalents. This is not an incremental improvement; it’s a fundamental re-engineering of a critical component that directly translates into a drastically extended service life.

The financial implications are immediate. By significantly reducing the frequency of pipeline replacements, the technology attacks a major source of capital outlay and operational downtime. Moreover, SCGC engineered the material for seamless integration. SCGC™ HDPE S999PC meets ASTM G65, ISO 9080, ISO 15527, ISO 13477, ISO13479 standards and can be reliably welded to existing PE100 and PE112 pipes. This compatibility allows companies to upgrade their infrastructure strategically without incurring the cost of a complete system overhaul.

The New ROI: Where Profitability and Sustainability Converge

The most compelling aspect of this technology is how it intrinsically links economic gains with a superior ESG profile. For modern investors, managing environmental impact is synonymous with managing risk, and SCGC™ HDPE S999PC provides a powerful tool to de-risk operations while boosting the bottom line.

The first dividend is drastic waste reduction. A longer service life inherently means less discarded pipe material and less consumption over a project's lifespan. This aligns with circular economy principles, especially as the material itself is 100% recyclable.

Second, and of growing importance, is the mitigation of microplastic pollution. The abrasive action of slurry transport on standard polymer pipes releases microscopic plastic particles into the environment. With its superior wear resistance, SCGC™ HDPE S999PC significantly diminishes the generation of these pollutants. This is no longer a peripheral concern but a direct response to a mounting regulatory and social issue, protecting a company’s ‘social license to operate’.

Finally, the extended durability contributes to a lower carbon footprint. By minimizing the need for manufacturing and transporting replacement pipelines, the technology reduces the embodied carbon associated with infrastructure maintenance.

This integrated approach has already been proven in the field. SCGC has a track record of supplying reliable piping systems for demanding applications. This demonstrates the material's capability to perform in critical, real-world conditions.

In conclusion, the emergence of advanced materials like SCGC™ HDPE S999PC signals a pivotal shift. It collapses the false dichotomy between profit and planetary responsibility, creating a business case where the most durable and efficient solution is also the most sustainable. The 2.3x advantage in abrasion resistance is more than a performance metric; it is a blueprint for a future where industry thrives not in spite of its environmental commitments, but because of them.