The year 2025 is marked by uncertainties across multiple dimensions—political, social, environmental, and economic. These uncertainties are not confined to Thailand alone. Looking across the globe, a multitude of shifts are sending strong signals for individuals and businesses to swiftly adapt in order to remain resilient within a highly volatile global context.

-----------------------------------------------------------

All Forecasts Indicate a Global Economic Slowdown in 2025

The global economy is under pressure from heightened political uncertainties and increasingly stringent trade policies, particularly tariff hikes and retaliatory trade measures among global superpowers such as the United States, China, and the European Union. These factors have led to a slowdown in numerous national economies, prompting investors to adopt a wait-and-see approach as they anticipate clearer policy direction and responses to this round of trade disputes.

UN Trade and Development (UNCTAD) has revealed data showing heightened volatility and uncertainty in financial markets. The Economic Policy Uncertainty Index has surged to its highest point in decades. Meanwhile, international organizations including the IMF, World Bank, and OECD (Organisation for Economic Co-operation and Development) have all projected a global GDP growth rate for 2025 of only 2.3–2.9%—the lowest level since the 2008 financial crisis (excluding the COVID-19 period).

US Tariffs: A Barrier to Global Economic Growth?

Tariffs are taxes imposed by one country on goods imported from another and are commonly used to protect domestically produced goods by increasing their competitiveness. In 2025, this term has come under the spotlight once again, driven by U.S. trade policies that have significantly increased import tariffs, widely known as US Tariffs. These began with higher tariffs on imports from major trade partners such as China, Canada, and Mexico, followed by additional tariffs on other trading nations, including Thailand.

The impact of US Tariffs extends beyond the immediate trading partners. They are expected to reduce U.S. GDP by approximately 0.6–1.0% in 2025 due to weaker exports and subdued domestic demand. From a global trade perspective, the World Trade Organization (WTO) estimates that global trade volumes will decline by at least 0.2%, potentially reaching a 1.5% drop if trade tensions escalate further.

In light of uncertainties that may impact the global economic system—including rising trade costs, shrinking trade volumes, and heightened financial market volatility—businesses must rapidly recalibrate and seek to enhance their competitiveness. This includes strengthening financial flexibility, adopting robust risk management practices, leveraging digital technology to reduce costs and gain strategic advantages, developing new business opportunities, and fostering a resilient and adaptable organizational culture. Collectively, these approaches will equip businesses to better withstand the challenges posed by trade policies and tariff barriers and pursue sustainable growth.

SCGC’s Strategy to Enhance Competitiveness and Unlock Growth Opportunities

While the global economy continues to face multifaceted pressures and the petrochemical sector remains volatile with intense competition, SCGC remains well-prepared to navigate change. The company has adopted strategic cash flow management to strengthen its financial position and is proactively adjusting both short-term and long-term strategies to reinforce its business capabilities. SCGC’s short-term strategies include:

Reducing raw material costs, optimizing working capital, and lowering expenses by leveraging Digital and AI technologies.

Accelerating the development of High Value-Added Products & Services (HVA), including Green Polymers that align with megatrends and the evolving needs of brands and consumers

Expanding integrated Service Solutions businesses

Growing the PVC fabrication (finished PVC products) business.

Leveraging Expertise to Capture Business Opportunities Amid Global Economic Shifts

In today’s uncertain world, a steadfast commitment to innovation is key to overcoming business challenges. This principle has long guided SCGC. Backed by a team of experienced experts, SCGC continues to invest in international-standard research and development to deliver High Value-Added Products & Services (HVA) and Green Polymers. It also integrates digital technologies to optimize the supply chain and leverages its deep expertise to expand into new business domains.

International-standard Innovation Management to develop high-value products and services (HVA) and Green Polymers, leveraging technological expertise and deep customer insights. The company fosters an innovation-driven culture (Open Innovation) both internally and through collaborations with external partners. SCGC established the integrated innovation center “i2P Center” (Ideas to Products), supported by a global innovation network, to help clients, brand owners, institutions, and business partners discover new ideas and trends and convert them into growth-driving innovations.

The i2P Center (Ideas to Products) collaborates closely with clients, from understanding their needs to brainstorming and business development, culminating in tangible innovations. The center supports end-to-end prototype development, with an expert R&D team specializing in polymer materials, product design, and fabrication, enabling the rapid delivery of prototypes that pave the way for commercial innovation.

The i2P Center has developed numerous HVA products, especially those aligned with global megatrends—such as environmentally friendly polymers, automotive innovations, urbanization and infrastructure solutions, healthcare and medical advancements, and alternative energy. These innovations enhance consumer lifestyles. Currently, the i2P Center manages over 100 innovation projects and launches an average of 25–30 new products annually, effectively responding to consumer trends and client demands.

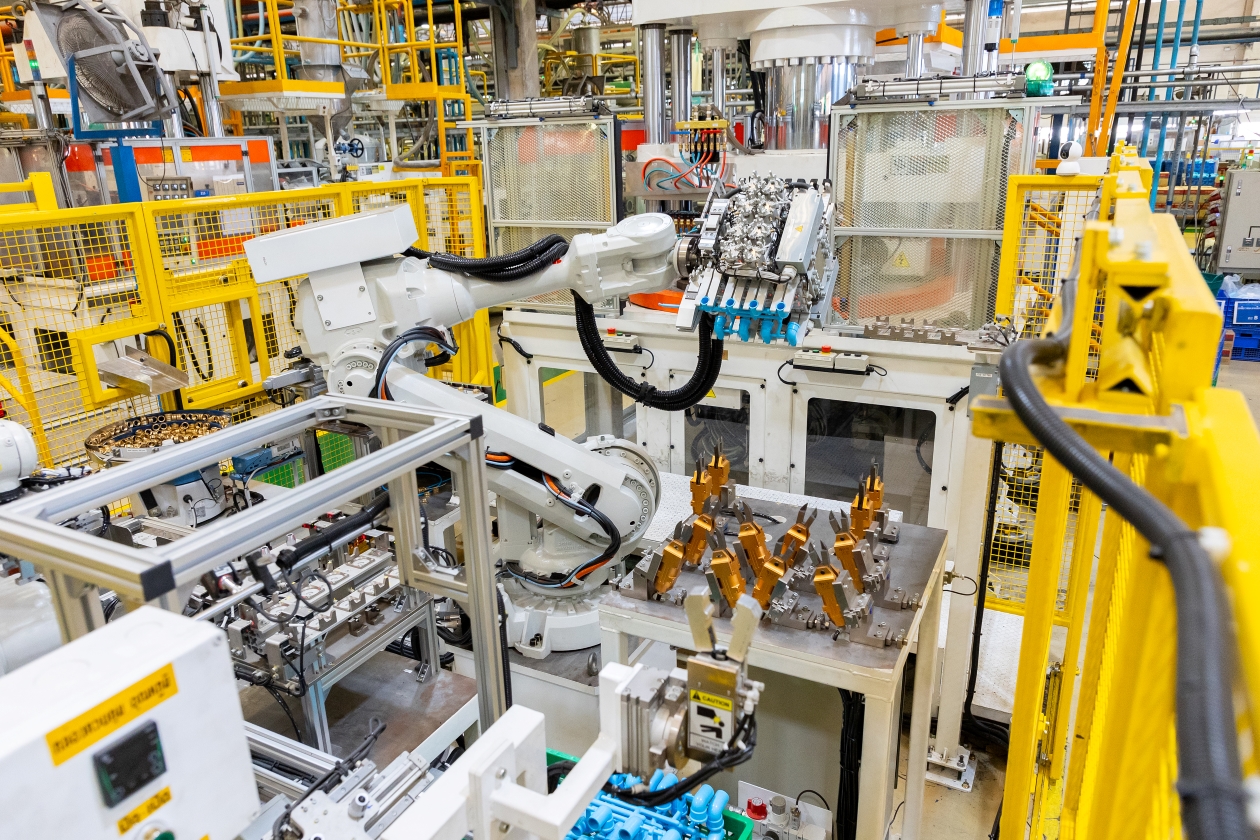

Applying digital technology to improve supply chain efficiency, particularly through enhanced plant management using digital solutions such as Artificial Intelligence (AI) and Robotics & Automation systems. These technologies boost productivity, improve safety, and enable precise machinery performance forecasting. Tailored for each plant, such systems have been implemented at Nawaplastic Industries, which manufactures PVC pipes, fittings, and fabricated products.

Nawaplastic Industries Co., Ltd. (NPI), a member of SCGC, has achieved a world-class Robot Density in its manufacturing plants. By implementing Robotics & Automation, NPI has enhanced product quality, efficiency, and safety. Every process adheres to environmental best practices under the Green Industry framework. The company has been certified as an Eco Factory and was the first in Thailand to receive both the Carbon Footprint of Product (CFP) and Carbon Reduction Label (CFR). Its low-carbon innovations reduce CO₂ emissions by approximately 2,180,000 kgCO₂eq/year—equivalent to planting more than 260,000 teak trees.* (*Based on the Corporate Carbon Footprint (CFO) of Nawaplastic Industries Co., Ltd. in 2023. One teak tree absorbs approximately 8.6 kgCO₂eq, according to the Thailand Greenhouse Gas Management Organization (TGO).)

Nawaplastic Industries Co., Ltd. (NPI) is a leading pipe manufacturer in Thailand and ASEAN, operating under the flagship brand “SCG Pipes,” as well as vinyl door and window products under the “WINDSOR” brand. With over 55 years of experience, NPI has continually developed product and service innovations to meet diverse customer needs and improve quality of life, delivering high-quality products via state-of-the-art automated manufacturing systems certified to both domestic and international standards. More information: www.nawaplastic.com

Expanding and leveraging SCGC’s expertise to create new business opportunities beyond polymer leadership, utilizing accumulated knowledge to build future growth ventures.