Dive into the world of innovation and groundbreaking initiatives as SCGC explores the transformative solutions revolutionizing the future of plastic recycling.

-------------------------------------------------------------------------------------------

ARE WE RECYCLING PLASTICS MORE OVER TIME?

Globally, plastic recycling remains a significant challenge, with only about 9% of plastic waste being mechanically recycled, while the rest ends up in landfills, nature, or is incinerated. According to the Thailand’s Pollution Control Department, only 25 % was sorted and recycled and the country produced 3 million tons of single-use plastic waste, accounting for 11 % of the total municipal solid waste generated.

From the packaging that keeps our food fresh to technology that makes modern cars lighter to components that help make solar panels a more effective source of renewable energy, plastics are integral to realizing a sustainable future. They make consumer goods affordable, convenient, efficient, and even safer. Considering all the benefits and its versatility in shaping and forming, plastic is an essential material still.

The United Nations and member countries are working on a legally binding agreement to end plastic pollution, with negotiations set to continue through 2025. Other collaborative efforts need to significantly increase, necessitating innovative solutions and groundbreaking initiatives that are shaping the future of plastic recycling.

-------------------------------------------------------------------------------------------

#1 CHEMICAL RECYCLING

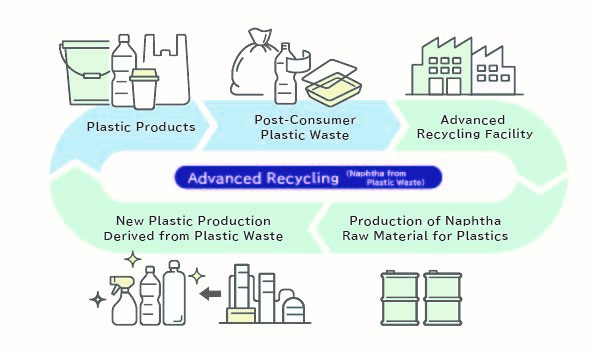

Chemical recycling is emerging as a groundbreaking innovation in the realm of plastic recycling, offering a transformative solution for addressing plastic waste. Unlike traditional mechanical recycling, which is limited to specific types of plastics, chemical recycling breaks down plastics at the molecular level, enabling the processing of mixed and contaminated materials. This innovative approach aligns with sustainability goals by reducing plastic waste and creating a circular economy for plastics. Technologies such as depolymerization, pyrolysis, and gasification are at the forefront of this movement. Depolymerization disassembles plastic polymers into their original monomers, which can be reused to produce new plastic products. Meanwhile, pyrolysis and gasification convert plastics into valuable fuel or feedstock for industries like energy and chemical manufacturing. By integrating chemical recycling into their strategies, businesses can enhance their ESG (Environmental, Social, and Governance) performance. This approach not only mitigates environmental impact but also creates new opportunities for industries to thrive while addressing the global plastic waste crisis.

SCGC transforms hard-to-recycle used plastics through a recycling process into Circular Naphtha, a new raw material, which is then used to produce Certified Circular Polyolefin Resin. This resin offers properties equivalent to virgin plastic resin and is certified under ISCC Plus (International Sustainability and Carbon Certification) across the entire supply chain, making SCGC the first in ASEAN to achieve this. The resin can be used to manufacture food-grade packaging while also addressing waste accumulation issues and helping to mitigate the impacts of global warming.

#2 BIOPLASTICS

Bioplastics represent a groundbreaking innovation in the realm of plastic recycling in 2025, offering a sustainable alternative to traditional petroleum-based plastics. Derived from renewable sources such as cornstarch, sugarcane, or algae, bioplastics are designed to be biodegradable or compostable, reducing their environmental footprint. Recent advancements in bioplastic technologies have significantly enhanced their durability and functionality, making them viable for a wider range of applications while lowering production costs. This progress aligns with global sustainability goals, addressing the urgent need to reduce plastic waste and transition to eco-friendly materials. Some companies are even developing bioplastics that can be recycled alongside conventional plastics, simplifying the recycling process and fostering a circular economy. As bioplastics continue to evolve, they hold immense potential to reshape the plastic industry, paving the way for a greener future.

SCGC’s Braskem Siam, in collaboration with Braskem and Thailand’s Mitr Phol Bio Fuel, is evaluating the construction of a groundbreaking bio-ethylene production plant at the Map Ta Phut Industrial Estate in Rayong Province. This facility will combine Braskem Brazil's advanced bioplastics technology with SCGC's Green Innovation, marking the first plant of its kind outside Brazil and the first bio-ethylene production plant in Asia. The plant aims to produce bio-ethylene from ethanol derived from agricultural products, offering a sustainable alternative to fossil fuel-based ethylene, with an impressive production capacity of 200,000 tons per year. Scheduled for completion by 2027, the facility represents a significant milestone in advancing sustainable solutions in the region. Braskem Siam has an estimated ethanol feedstock demand exceeding 450 million liters annually and is actively sourcing high-potential ethanol feedstock both domestically and internationally to support this ambitious project.

#3 MATERIAL REDUCTION

Lightweighting has emerged as a key innovation in packaging design, offering a practical solution to enhance sustainability while supporting plastic recycling efforts in 2025. By reducing material usage without compromising strength, durability, or functionality, lightweight packaging minimizes environmental impact and lowers production costs. This approach is gaining momentum across industries such as food and beverages, e-commerce, and personal care, where packaging significantly influences consumer perception and product safety. As more brands adopt lightweighting strategies, they not only address consumer demand for eco-friendly solutions but also align with ESG goals. This transformative trend reflects the brand owners and polymer companies' commitment to reducing its carbon footprint and advancing a circular economy, paving the way for a more sustainable future.

SMXTM Technology, a high-quality plastic resin production technology unique to SCGC, creates plastic resins that are stronger, stiffer, and more durable. This technology enhances the properties of plastic resins, allowing for less plastic use while maintaining high quality, lightweight, and reducing carbon dioxide emissions.

#4 WASTE MANAGEMENT ECONOMY

One of the key trends to watch in 2025 is the application of the Sharing Economy in waste management. Unlike traditional models that focus on independent growth, the sharing economy emphasizes the collaborative use of resources, driven by digital platforms. This approach has led to the creation of products and services that meet the needs of a broader audience. In the context of waste management, examples of the sharing economy include the shared use of recycling infrastructure, waste collection services, and enhanced collaboration in waste management expertise. These initiatives help reduce costs and significantly improve efficiency. This transformation promotes sustainability, fosters community engagement, and supports plastic recycling by maximizing resource utilization and minimizing waste. As digital platforms continue to grow, waste management models based on the sharing economy are expected to expand significantly this year and, in the future, driving transformative changes in the waste management landscape. These innovative models align with ESG principles (Environmental, Social, and Governance), focusing on responsible resource management and reducing environmental impact. By integrating technology and fostering collaboration, the sharing economy not only revolutionizes waste management but also paves the way for a more sustainable and efficient future. Communities and organizations are working together to create a circular economy where resources are reused effectively, and waste is tangibly reduced.

The Bang Sue Model is SCGC’s waste management initiative, launched in 2018, aimed at optimizing resource usage and promoting waste segregation at the source. This model empowers employees to correctly recycle and reuse resources, contributing to a sustainable waste management system. Over time, the initiative expanded beyond the organization, inspiring various impactful projects such as the Waste-free Community, Upcycling Milk Pouches, and Wake Up Waste.

We have strengthened our circularity efforts through key partnerships. Collaborating with Global House, SCGC transforms used plastics from their retail stores and distribution centers into eco-friendly plastic bags using High-Quality PCR from SCGC GREEN POLYMER™. Last year SCGC signed an MoU with HomePro to introduce Thailand's first "Closed-Loop Circular Appliances" initiative, focusing on recycling electrical appliances to protect the environment.

#5 ENHANCED SORTING AND CLEAUP

The fight against plastic pollution is witnessing groundbreaking innovation through advanced technologies aimed at both cleanup and recycling. Ocean plastic cleanup technologies are emerging as critical tools to combat pollution at its source. These systems, including passive drift devices, autonomous surface vessels, and large-scale floating barriers, are designed to collect and remove plastic waste from oceans, rivers, and other water bodies. By trapping and collecting debris, these technologies prevent further harm to marine ecosystems. Some initiatives are even exploring ways to convert ocean plastic waste into usable products, fostering a circular economy and aligning with sustainability goals. Equally transformative are enhanced sorting technologies, which are revolutionizing plastic recycling processes. Traditional sorting methods often face limitations, leading to contamination or incorrect categorization of materials. However, automated systems equipped with advanced sensors, artificial intelligence, and machine learning are addressing these challenges. These technologies can precisely identify and separate plastics based on chemical composition, color, and shape, ensuring higher efficiency and purity in recycling streams. Improved sorting reduces contamination, enabling the production of higher-quality recycled plastics and supporting a circular economy. Both ocean cleanup and enhanced sorting technologies exemplify the integration of ESG (Environmental, Social, and Governance) principles into waste management strategies. These innovations not only tackle pollution but also advance sustainable practices, paving the way for a cleaner and more eco-conscious future.

SCGC's Coastal Development and Conservation Project has been actively ongoing for over a decade since its launch in 2005. This initiative brings together coastal communities, local municipalities, businesses within the Map Ta Phut Industrial Estate, and SCGC employees in a collaborative effort to protect and restore coastal environments. Activities include regular beach cleanups across multiple sub-districts, such as Mueang, Ban Chang, Phe, and Klaeng in Rayong Province, aimed at removing marine debris that washes ashore during seasonal tides. Additionally, SCGC partners with various organizations to participate in the annual International Coastal Cleanup in Rayong Province, promoting the idea that waste can be transformed into a valuable resource. The project also emphasizes the importance of proper waste sorting and disposal practices to help reduce marine litter, fostering a shared commitment to environmental sustainability.

Wake Up Wasteis one of SCGC's green solutions designed to optimize waste management processes from the source to recycling with maximum efficiency. It comprises two key components: 1) Digital Waste Management Platform. The platform facilitates efficient and transparent waste purchasing and transportation to recycling facilities. It also enables data collection, ensuring a seamless and traceable process.; 2) Mobile Recycling Compactor Service: Equipped with advanced compression technology, this mobile service reduces waste storage space by 5-10 times. It encourages waste separation at the source, highlights the value of recyclable materials, and maximizes their reuse potential. Wake Up Waste not only enhances the efficiency of waste management but also promotes sustainable solutions to address environmental challenges in the long term.

The “5 Recycled Plastic Trends for 2025” update from SCGC marks a significant step forward in revolutionizing resource efficiency and strengthening the Circular Economy. Driven by SCGC's commitment to innovation and environmentally-conscious initiatives, we are not only creating cutting-edge technologies and solutions that align with global trends but also inspiring communities to collaborate in protecting our planet for a sustainable future.

----------------------------------------------------------------------

References and Image Credits: