PE Plastic Cap Industry Insight

Where is PE Plastic Cap?

Polyethylene (PE) plastic caps are a grounding in the packaging industry, known for their durability, flexibility, and excellent sealing properties. This article delves into the characteristics, applications, and benefits of PE plastic caps, highlighting their pivotal role in various sectors.

Characteristics of PE Plastic Caps

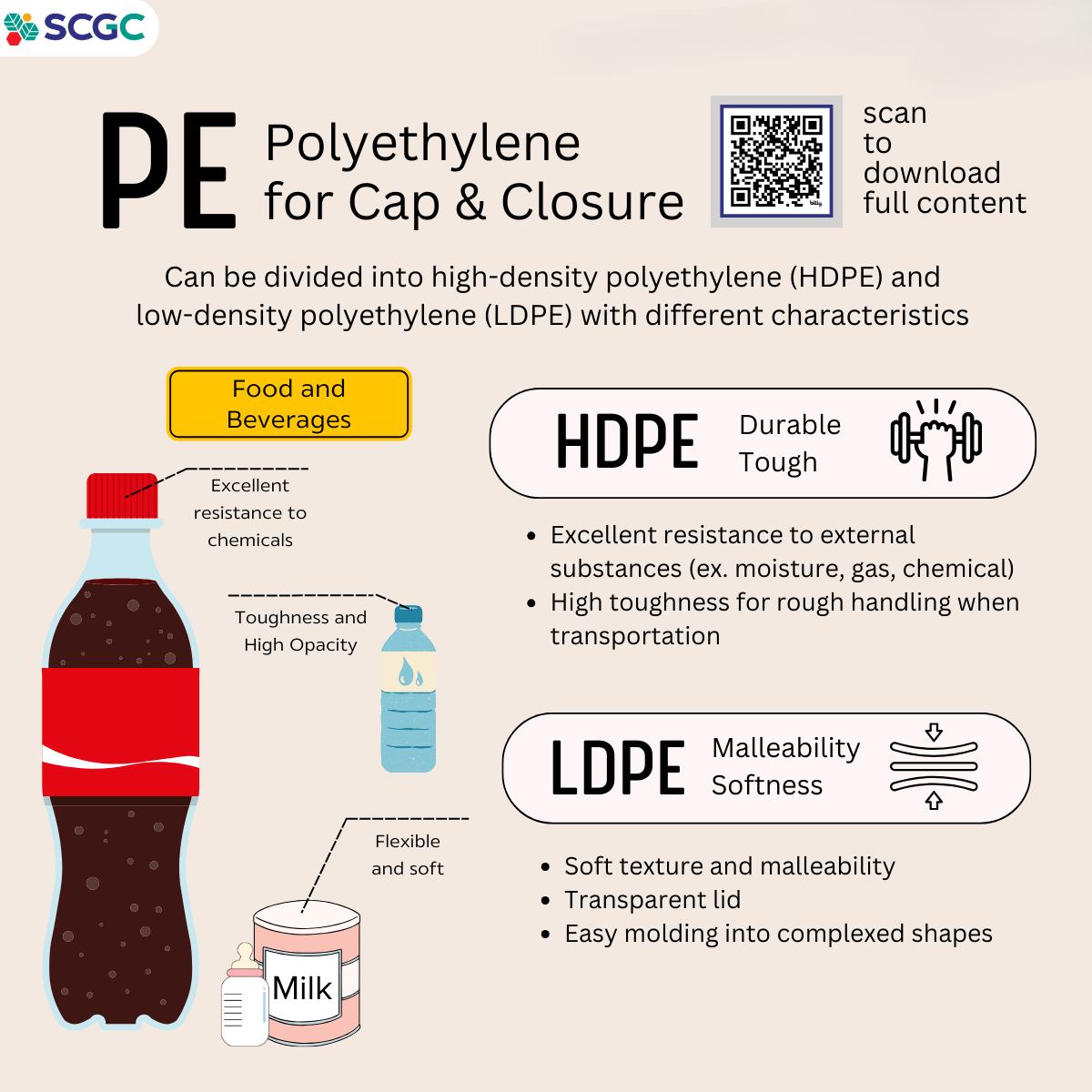

PE plastic caps are categorized into two main types: High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). Each type offers unique properties that make them suitable for different applications:

HDPE

Known for its high density, HDPE provides excellent resistance to moisture, gases, and chemicals. It is durable, tough, and can withstand rough handling during transportation and storage. HDPE caps are ideal for applications requiring a secure seal and resistance to impact.LDPE

This type of polyethylene is highly flexible and malleable, allowing for easy molding into complex shapes and sizes. LDPE caps and lids are mostly transparent.

Applications of PE Plastic Caps

PE plastic caps are widely used across various industries due to their versatility and reliability. Common applications include:

Food and Beverage Industry

PE caps are essential for maintaining the freshness and quality of food and beverages. They provide a secure seal that prevents contamination and extends shelf life. HDPE caps are particularly suitable for both carbonated and non-carbonated beverages, water bottles, and food containers. While, LDPE caps are suitable for a more flexible lid such as a powder milk packaging.

PharmaceuticalIndustry

In the pharmaceutical industry, PE caps must comply with regulatory standards and guidelines. They offer excellent sealing properties, ensuring the sterility and safety of medications.

Household Products Industry

PE caps are commonly used in household products due to their durability and chemical resistance. They provide convenience and functionality while preventing leakage and spillage.

Industrial Applications Industry

PE caps are used in industrial settings for products such as lubricants. Their resistance to a wide range of chemicals makes them suitable for protecting the contents from external contaminants.

Benefits of PE Plastic Caps

PE plastic caps offer several advantages that make them a preferred choice in the packaging industry:

1) Durability

Both HDPE and LDPE caps are known for their toughness and ability to withstand harsh conditions.

2) Chemical Resistance

PE caps provide excellent resistance to a wide range of chemicals, ensuring the integrity of the packaged product.

3) Flexibility

LDPE caps are highly flexible, making them suitable for applications requiring complex shapes and sizes.

4) Sealing Properties

PE caps offer superior sealing capabilities, preventing leakage and maintaining the quality of the contents.

5) Sustainability

PE is a recyclable material, aligning with the growing trend towards sustainable packaging solutions.

Conclusion

PE plastic caps are essential to the packaging industry, offering a combination of durability, flexibility, and excellent sealing properties. Their versatility makes them suitable for a wide range of applications, from food and beverage to pharmaceuticals and household products. As the industry continues to evolve, PE plastic caps will remain a vital component in ensuring product safety and integrity.

For more information, please visit https://www.scgchemicals.com/en/contact-us and choose the 'SCGC Innovation' topic to get in touch with our sales team.