From the pioneer of a chemical business in Thailand over four decades ago, SCGC now distributes its products to over 120 countries around the world, ranging from upstream monomers to downstream polymers as well as related and finished products, and has a total production capacity of 6.9 million tons per year, accounting for 19%, or almost one fifth of the total capacity in Southeast Asia (as of December 2021). With continuous domestic and regional investments, SCG Chemicals (SCGC) has established itself as ASEAN’s leading integrated chemical business that contributes to the growth of the industry and is ready to foster social and environmental sustainability.

What are the factors that have contributed to SCGC’s advance to the forefront of the region’s industry?

The Region’s Largest Production Bases

SCGC has production bases in three countries that are ASEAN’s three largest economies: Thailand, Indonesia, and Vietnam. Thailand serves as the main production base, while SCGC also invests in Indonesia through a 30.57% shareholding in Chandra Asri Petrochemical Tbk (CAP) and is in the process of constructing Long Son Petrochemicals Complex in Vietnam, where SCGC is the first company to make such an investment. Altogether, the market encompasses two thirds of ASEAN’s population and has continued to show steadily rising purchasing power, and having production bases across these three countries enables SCGC to promptly meet the demand of the market. In addition, digital technology has been applied to the entire supply chain to further elevate operational excellence.

Integrated Vinyl Manufacturer

Based on the production capacity by shareholding according to NexantECA, SCGC is ASEAN’s largest producer of polyvinylchloride (PVC) with a PVC resin output of 0.886 million tons per year and an output of finished PVC goods of 0.43 million per year. It is also among a handful of vinyl producers in the world to have expanded to downstream businesses towards high value-added finished goods.

SCGC’s vinyl business is divided into two groups: PVC resin and compounds and finished PVC-based products, such as PVC pipes and joints, PVC hoses, and PVC window frames, door frames, and rain gutters. SCGC seeks to increase its PVC production capacity to exceed the expected demand and expand towards upstream businesses to reduce costs and be able to produce sufficient feedstock for its current and future operation as well as improve its capacity for PVC pipes, joints, and other high value-added PVC products to accommodate the growing demand for infrastructure in ASEAN.

Development of HVA Products And Services

High value-added (HVA) products and services have always been a R&D focus for SCGC, and they accounted for 35.8% of the total revenue from sales in 2021. In addition, SCGC is working to accelerate breakthrough technology that will drive the development of new products to meet the needs of the global market.

SCGC has established R&D centers in Thailand and overseas, such as in Britain and Norway, to accelerate research commercialization and meet business, social, and environmental needs. It employs over 560 researchers and tech specialists both domestically and internationally (as of December 31, 2021) and has tech networks and partnerships with world-class universities and institutes.

In addition, SCGC constantly seeks new partnerships and technologies through investments in startups and venture capital funds and currently owns over 473 patents* (as of December 31, 2021).

Integrating Digital Technology Across The Supply Chain

SCGC is a leader at the forefront of the industry that applies digital technology to its operations across the value chain and has always developed digital innovations that elevate the industrial standard.

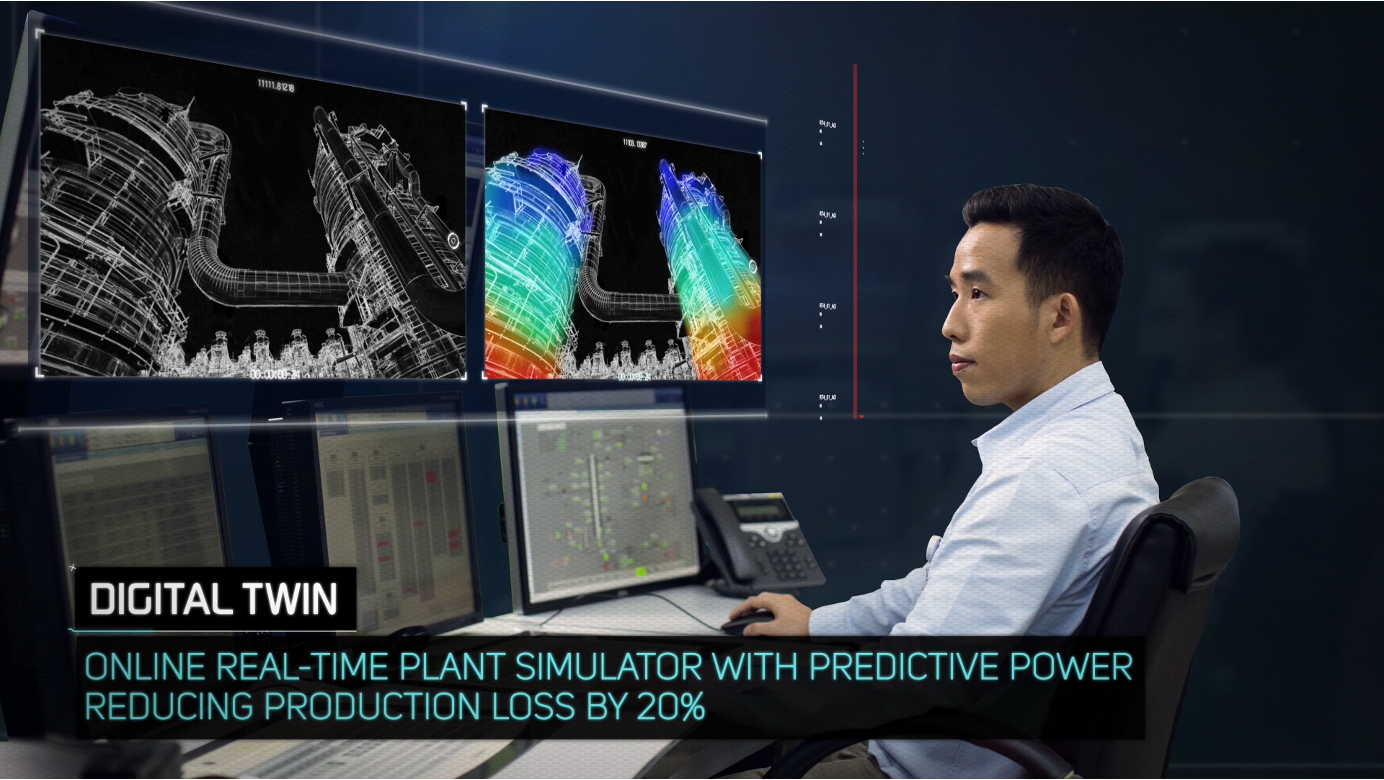

To maximize feedstock sourcing efficiency, SCGC has adopted machine learning to make a market forecast based on basic data and make procurement decisions that better align with customer demand. As for the manufacturing process, SCGC has developed and integrated its platforms by applying machine learning, digital twin or simulation, robotics, and the Internet of Things to optimize the business process and maximize reliability.

For asset performance management (APM), SCGC utilizes a digital reliability platform that can predict the health of the equipment in use in order to monitor its efficiency and systemically carry out maintenance to reduced unplanned downtime. Recently, SCGC has partnered with Critical Facility (Thailand) Co., Ltd. (CFT), to develop an advanced integrated lightning protection solution to elevate safety standards for operators in industrial plants and prevent damage to equipment and machinery, which may result in operational disruptions.

To cater to customers, SCGC has also developed a digital commerce platform (DCP), which offers customers real-time end-to-end data visibility. This integrated platform not only cuts down consumer waiting time by 70% but also enables customers to track order status anytime from everywhere as well as makes it possible to collect customer voices for data analysis and the development of new products.