Chemicals Business, SCG, is committed to developing advanced technologies to promote Thailand's competitiveness. It consistently lends its know-how and innovations developed internally or through open collaboration to improve people's quality of life.

In this particular state of the COVID-19 pandemic, Chemicals Business, SCG, remains intact to develop innovations. It has recently launched "SCG PP Melt-Blown," high-value-added plastic resins for melt-blown fabric production to serve the medical industry needs. The product has been the first in ASEAN to be certified to meet international standards.

The First's Internationally Certified in ASEAN

Plastic is one of the widely-used substitute materials across industries. In the medical world, medical-grade plastic material is opted for use because of its unique properties designed to meet medical and safety requirements. The medical-grade plastic materials must adhere to two major certification standards: ISO 13485 and ISO 14971.

Demand for Medical devices

Demand for medical devices and equipment has significantly surged across the globe, chiefly since the COVID-19 pandemic onset at the end of 2019. Under normal circumstances, the demand for surgical face masks for healthcare workers would be around 28 million pieces per day. However, the pandemic situations would have increased such the demand by possibly another 12 million per day. For Thailand, the Department of Internal Trade has said that the domestic need for face masks stood at 30-40 million pieces per month under normal circumstances. The COVID-19 pandemic has quintupled the demand to 200 million pieces per month.

SCG PP Melt-Blown is high-value-added plastic resins that can produce melt-blown fabric for medical purposes. The innovation has been tested by leading institutes and it is now being developed with medical manufacturers to produce melt-brown fabric materials and bring about the solution for healthcare workers and mask wearers to protect themselves from germs or fine particles.

Plastic Resin for face mask filter sheet

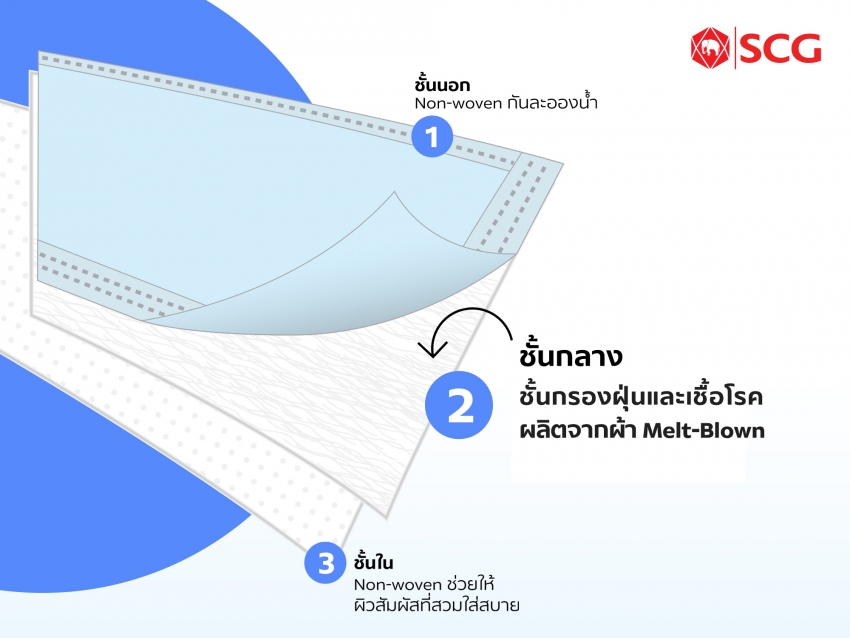

Developed by Chemicals Business, SCG, SCG PP Melt-Blown is a high value-added plastic resins used to produce face mask filter sheets from Melt-blown Nonwovens, a preferable fiber material made from plastic resins. The non-wovens have a fiber diameter in the nanometer and micrometer range. This unique property makes it a popular choice for filters, insulations, and filter sheets.

FDA Regulation for Face Mask

According to the requirements mandated by the Food and Drug Administration (FDA) under the Ministry of Public Health, the production or import of surgical face masks must adhere to the industrial product standard regulations for single-use hygienic masks (TIS 2424-2562). The face mask must perform Bacterial Filtration Efficiency (BFE) not less than 95% at three microns.

The SCG PP Melt-Blown innovative polypropylene resin is tested and approved by the leading institutes to produce fibers of 1-5 microns in diameter, which can filter out fine particles such as PM2.5 and germ with a Particle Filtration Efficiency (PFE) rating of >95% and Bacteria Filtration Efficiency (BFE) rating of >95%, the performance that meets the Public Health Ministry's FDA criteria.

Build Economic Dynamic in Asean Health Industry

Apart from being a filter material that can prevent bacteria and particles, SCG PP Melt-Blown can reduce the dependence on the import of plastic resins for face mask productions, a solution that can address the shortage in the supply chain of the country's face mask manufacturing activities. This will bring about increased access to medical resources for healthcare workers and the public. Above all, it is an efficient way to enhance the country's face mask production competitiveness.

"We strive to develop innovation in the health and wellness space to improve people's quality of life and meet the SDG 3, which to ensure healthy lives and promote well-being. In our view, plastic materials are the essential substitute and highly necessary for the manufacture of products within the health and wellness industry. It can reduce the dependence on importing such plastic resins and medical devices to a considerable extent, resulting in better medical access to healthcare workers and the public," said Tanawong Areeratchakul, president of Chemicals Business, SCG.