“Some patients have never walked for 40 years because they have never had access to prostheses. If you go to the prosthesis casting room or see people coming to our foundation early in the morning hoping that they would be able to walk the next day, you’ll understand what I’m doing all this for.”

The touching words of Assoc. Prof. Vajara Rujiwetpongstorn, M.D., Board Member and Secretary General of the Prostheses Foundation of H.R.H. the Princess Mother, not only reflect the quality of life of people with disabilities in Thailand but also show an opportunity where SCG can apply its expertise in material science and design to developing an innovation that enables these people to fully integrate into society with confidence and use their potential for society.

Development towards the Better

For over 30 years, the Prostheses Foundation of H.R.H. the Princess Mother has offered assistance to lower limb amputees, in keeping with the aspiration of H.R.H. Princess Srinagarindra to see people with disabilities able to live a normal life and earn their own livelihood. To this end, the foundation seeks to partner up with private companies with capabilities to make parts of prosthetic legs more functional and durable, and SCG is among Thailand’s leading companies that have played a role in advancing this initiative.

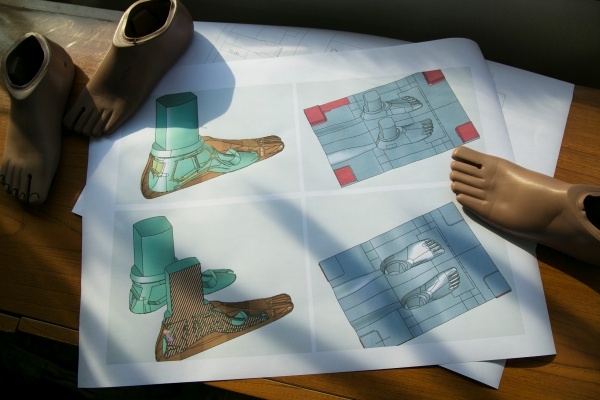

The task that SCG was mainly responsible for was the development of a new prosthetic foot that was more ergonomically correct.

Leveraging its expertise in material science and design as well as years of experience in medical equipment development, SCG started out by tackling the challenge of selecting materials, prioritizing quality and affordability. The SCG team eventually decided on a material used in the automotive industry – a PP composite mixed with fiberglass, which gave the material greater strength and made it lighter. The material was then applied to a new keel design. Instead of a C-shape keel, which created a direct pressing force and could thus lead to breakage, the SCG team designed the new keel in the shape of the letter A, which better supported and distributed pressure, and gave it a beehive structure. This design was further developed and eventually met industrial standards.

The keel developed by the SCG team could support 90 kilograms maximum and could be used for at least 2,000,000 steps, fulfilling actual functional requirements effectively.

Collaboration for the Better

As the material for the foot shell needed to be durable, resilient, tough, flexible, light and aesthetically resemble a real foot, SCG also collaborated with Dow Thailand Group to obtain the perfect plastic material.

The prosthetic foot project reflects how SCG always prioritizes open collaboration and integrates it into every dimension of the working process. What also captured this very spirit was the collaboration with Rubber Soul Company Limited to further develop the improved prosthetic foot, in which Rubber Soul designed the mold and developed a compound material that would create lightweight, durable, and affordable prosthetic feet that were similar to human feet in properties and could be easily purchased and replaced.

Opportunity for the Better

The innovative prosthetic foot jointly developed by SCG, Dow Thailand Group, Rubber Soul Co., Ltd., and the Prostheses Foundation of H.R.H. the Princess Mother has not only brought technological advancement to the world but has also renewed hope and given a new life to many people.

SCG continues to actively develop innovation and is ready to contribute to a better quality of life and grow sustainably with everyone. Watch the video on the “new prosthetic foot” here: https://bit.ly/3p2qD8g