Standing out among the highlighted products of Chemicals Business, SCG in the past few years is SMX™ Technology, which has enabled the development and manufacturing of stronger HDPE (High Density Polyethylene). Thanks to their improved strength, plastic resins developed with this technology can better meet product specifications, and less material is required to achieve the same mechanical properties, which supports the circular economy.

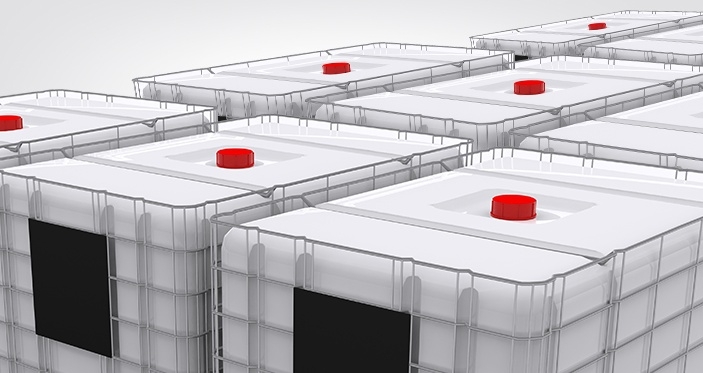

One of the plastic resins made possible by this innovative technology is SMX™ H551BU, an HDPE resin developed for the manufacturing of industrial-grade 1000-liter intermediate bulk containers (IBC), which are mostly used to transfer highly reactive or corrosive chemicals, such as hydrogen peroxide and hydrochloric acid. These tanks can also be stacked and moved with forklifts, leading to their widespread use in large industrial plants.

As such, the plastic for IBC manufacturing must enable these tanks to withstand corrosion and make them strong enough that they do not leak or crack when moved or stacked, which could lead to injuries and damage not only to the company’s employees and properties but also to its reputation regarding its safety standard. As they have to be maintained to meet the specifications, these basic properties add another layer of complexity to any attempt to develop a plastic resin that reduces material consumption.

Depending on the design of the IBC, SMX™ H551BU makes it possible produce a tank with a thinner wall and around 10% reduced weight, while maintaining product performance. Thanks to its high melt strength, the innovative plastic resin has easy processing allowing good thickness distribution and energy consumption reduction. In addition, the transportation of lightweight IBCs produced with this resin takes less energy and releases less carbon dioxide, making them truly eco-friendly throughout their life cycle.

In the development of HDPE SMX™ H551BU, SCG worked closely with two world-class bulk container producers, Schutz and Pack Delta, to pinpoint usage needs and convert them into corresponding properties that the resin needed to have to produce IBCs that would meet the needs of both manufacturers and end-users. In addition, tests were conducted to ensure that the resin met the UN Mark Certification for Packaging of Dangerous Goods (UN standards) so that a label could be put on the container and exported for sale.

Thanks to SMX™ Technology, the Chemicals Business, SCG, has successfully innovated a product that not only reduces costs for the plastic industry but also enhances resource maximization throughout the supply chain, from raw material producers and product manufacturers to end-users, which is in line with the principle of circular economy and will lead to business and environmental sustainability.

For more information, please email us at smx@scg.com