Enhancing the quality and standards of infrastructure, especially the public waterworks system can contribute greatly to uplifting people s quality of life. However, the materialization of this idearequires the full and sincere collaboration of allconcerned parties, or the reality would be similarto a jigsaw puzzle left unfinished.

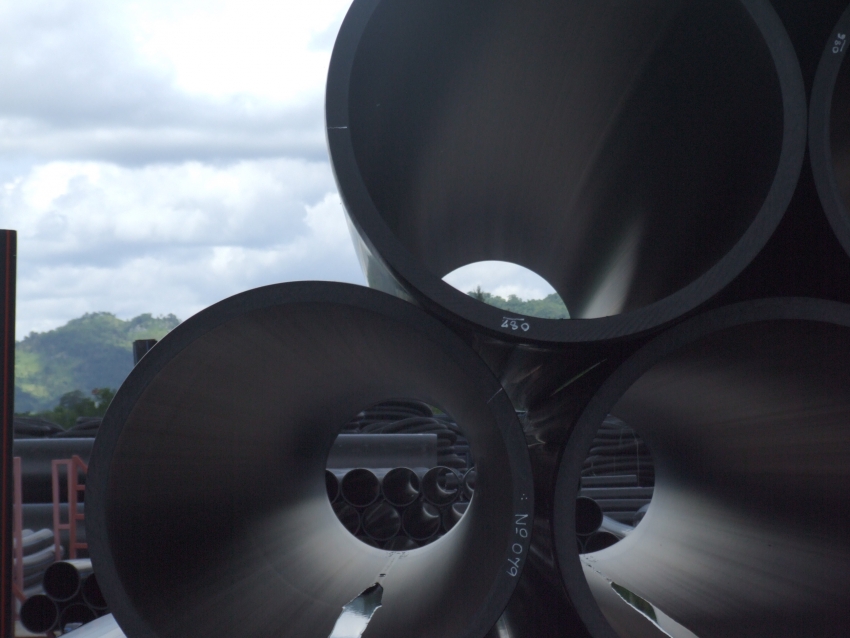

In Thailand, the public waterworks system has developed over the years. More recent efforts have seen the replacement of steel pipes with High Density Polyethylene (HDPE) pipes, which have been in use in many developed countries including Europe for more than half a century. Unlike steel pipes, HDPE pipes are free from rust and corrosion, making potable water clean and safe for consumers. Moreover, the installation of HDPE pipes is easy and hassle free, significantly reducing piping installation time and giving a long service life, which makes it worth the investment.

Over the years, the use of HDPE pipes in Thailand has encountered a multitude of challenges, especially the quality standards of the plastic pipes. This gave rise to the establishment of the TIS 982-2548 standard specifications to determine the sizes andpressure grades suitable for HDPE pipe applications. However, given the specifications falling short oncovering the component of plastic materials, some manufacturers have sought to use recycled materials for the manufacturing process to save costs, resulting in numerous problems as follows: Pipe leaks or breaks can cause disruption and safety issues for users. The agencies entrusted with the productionand expansion of public waterworks network are subject to costs incurred to repair the damaged piping system, thereby failing to achieve cost-effectiveness due to the shorter service life of the pipes. Several manufacturers of HDPE pipes that meet the quality standards suffer from unfair price competition.

In the wake of these challenges, SCG Chemicals, together with other leading manufacturers of plastic resins and pipes in Thailand and the Thai Industrial Standards Institute (TIS) jointly set forth TIS 2559-2554 standard specifications for "Polyethylene Compound for Drinking Water Pipes" for use as criteria to inspect HDPE pipes down to the plastic material component. The specifications will help edge the pipes that do not match the quality standards out of the market.

Provincial Waterworks Authority (PWA), a major user of pipes in Thailand, is to adopt these specifications in inspecting the piping systems delivered by the contractors. For its part, SCG Chemicals provides academic and technical support,for example, organizing seminars to provide knowledge to PWA inspection engineers and assigning technical engineers and product development staff from SCG Chemicals to assist in pipe quality inspection. Added to this is the offering of a pipe inspection service at SCG Chemicals laboratories.

The establishment of such rigorous quality specifications has benefited the industry as a whole encompassing plastic manufacturers, HDPE pipes producers, pipe users, and consumers. For SCG Chemicals, the problems, opinions, and suggestions from pipe users and manufacturers have allowed for the further improvement of plastic resins and inspired the company to create more innovative HDPE products to accommodate future application needs.

On the other end, leading Thai HDPE pipe manufacturers including Thai-Asia PE Pipe Co.,Ltd., Wiik & Hoeglund Public Company Limited, and Thai Gow Gai Group Co., Ltd. are motivated to create products that meet quality standards, contributing to cost-effectiveness for users like PWA. With fair price competition, customers will be more concerned about quality than pricing, leading to future growth in the HDPE pipe market. Moreover, Thai manufacturers have promising potential to develop HDPE pipes that meet international standards, thus increasing opportunities for exports and enabling Thailand to be a major production base in the years to come.

Likewise, end-users like PWA can avoid problems associated with pipe leaks or breaks or a short service life. This significantly helps reduce repair costs and make it worth the investment and the expansion of public waterworks to larger areas. The convenience and safe, clean water enjoyed by the public will contribute to a better quality of life and a good service image for PWA consistent with the directionset forth by PWA Governor Ratana Kitchawan that reads:

"PWA plans to continually expand our services in various regions each year, which demands huge investment. As Thailand is gearing up for the AEC, it compounds the needs for adequate infrastructure to ensure a public waterworks system that meets a standard of excellence." The collaborative efforts of all concerned parties not only reflect their senses of social responsibility but also help drive the HDPE pipe industry toward a brighter future for all.